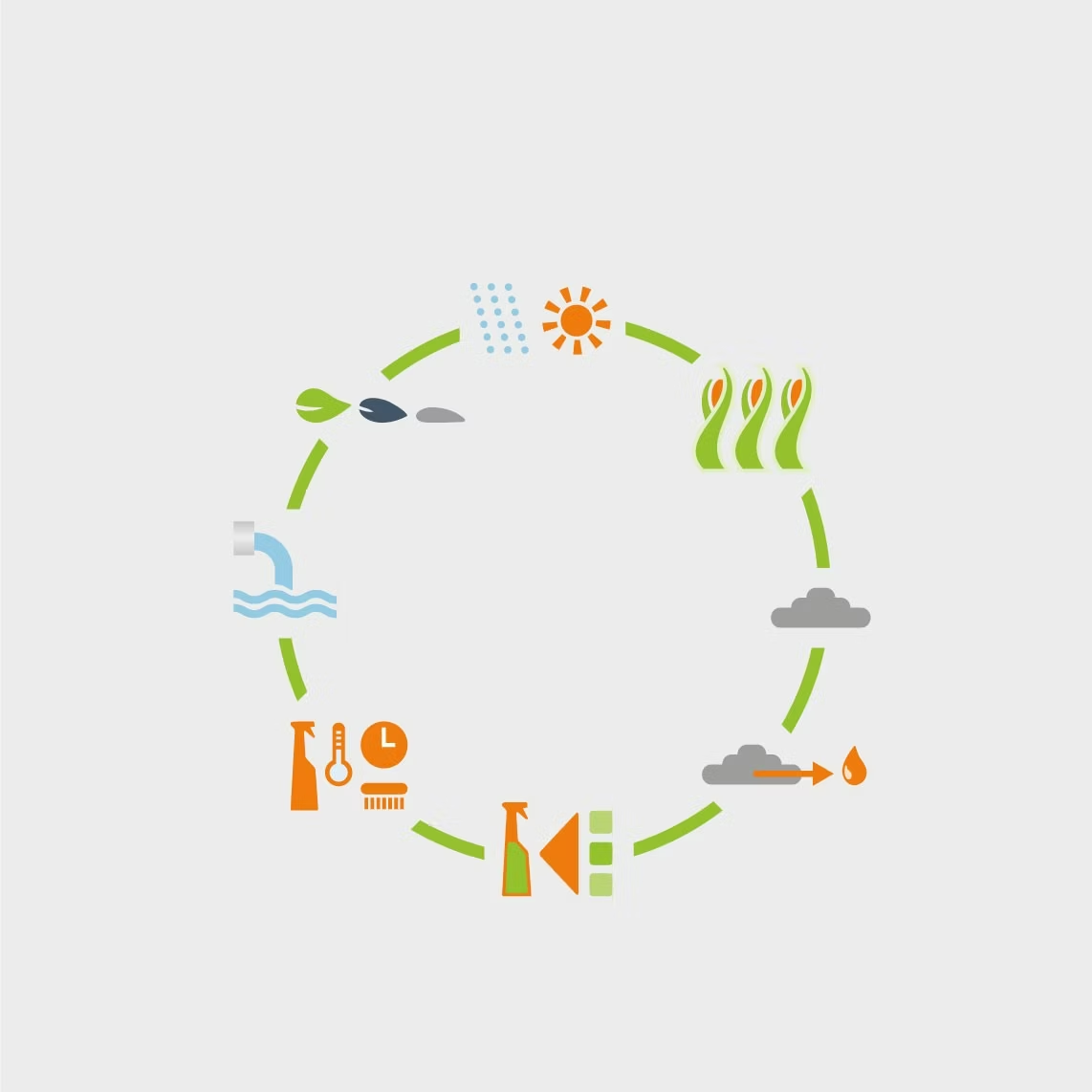

Circle of life - our surfactants and the ecosystem

Among other things, surfactants from renewable raw materials are used, which are produced, for example, during the processing of maize (maize residues/biomass).

They are contained in the LeraFloor® products as emulsifiers on the one hand and as surface-active substances on the other and, in conjunction with equally sustainable complexing agents, serve to increase the dirt-carrying capacity.

This means that the dirt emulsifies (binds) with the surfactants and is held in the cleaning solution by the complexing agent. It is then removed gently but very effectively - without damaging the surface.

The use of natural and renewable raw materials supports ecological and agricultural plant cultivation worldwide.

Natural drive

Solar radiation, CO2 and water are the natural drivers of the circular economy.

Renewable raw materials

We use maize plants and oils from sustainable plantations for our sugar surfactants.

Valuable biomass

is produced in the decomposition of the plants.

Extraction

of glucose, oils and fats.

Synthesis process

Conversion of fatty alcohols and glucose into an alkyl polyglycoside.

Cleaning

The surfactant is used for cleaning.

Waste water

The surfactants are decomposed in the sewage treatment plant at the latest.

Decomposition

What remains is water, CO2, minerals and biomass.

Natural drive

Solar radiation, CO2 and water are the natural drivers of the circular economy.

Renewable raw materials

We use maize plants and oils from sustainable plantations for our sugar surfactants.

Valuable biomass

is produced in the decomposition of the plants.

Extraction

of glucose, oils and fats.

Synthesis process

Conversion of fatty alcohols and glucose into an alkyl polyglycoside.

Cleaning

The surfactant is used for cleaning.

Waste water

The surfactants are decomposed in the sewage treatment plant at the latest.

Decomposition

What remains is water, CO2, minerals and biomass.

Product Benefits

Downloads

LeraFloor® assortment brochure

Service & Support

Our experts in Europe